Maytag Atlantis Washer Manual Remove Agitator From Ge

The Maytag Dependable washer series simply has a screw on the side of the agitator housing securing it to the shaft. The Performa, Norge and Atlantis models have a bolt in the centre of the agitator. Once you remove the bolt, the agitator will lift off the shaft and out of the washer. The Maytag MVWC565FW is part of the Washing machine test program at Consumer Reports. In our lab tests, Top-load agitator washer models like the.

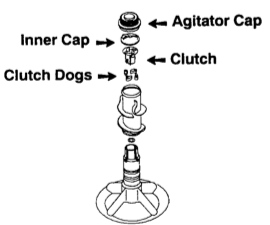

7-1 BASIC OPERATION The design uses a reversing motor, which is belted to both the pump and the transmission, using two different belts. At times, both one-speed and two-speed motors were used. When viewed from the top, the motor turns clockwise for the agitation cycle, and counterclockwise for the spin cycle. (Figure M-1) To switch between the two cycles, there is a brake in the hub of the drive pulley, and a clutch in the transmission.

During agitation, the brake keeps the transmission casing from turning, and the drive pulley turns the transmission shaft. During the spin cycle, the brake releases and the whole transmission starts slowly spinning around. Since the basket is attached to the transmission casing, it spins, too.

A clutch built into the transmission allows slippage until the basket gets up to speed. At the end of the spin cycle, the motor stops and the brake brings the basket to a stop. In the late '80's, Maytag redesigned the transmission. The result is the 'orbital' transmission, which has just a few moving parts and is serviceable in the machine. One is supposed to be able to replace the other directly.

Contents • • • • • • • Plot [ ] Siva () is an investigative who shares a live-in relationship with rich and bratty Madhu (). Things come to a head when Madhu starts a restaurant with a brother of her friend. Anbe aaruyire album audio song high quality download. They have hot-headed run-ins and even hotter patch-ups.

However, the gearing in the orbital is higher (the agitator agitates faster) so I would not replace one with the other unless absolutely unavoidable; for example, if the parts were unavailable. The motor is mounted on rollers which ride in a metal track. Springs attached to the motor mounting plate keep tension on the belts. The pump reverses with the motor, but there is no recirculation. When the washer is agitating, the pump is just sitting there spinning; it is not moving any water. 7-2 OPENING THE CABINET AND CONSOLE To access the belts, lean the machine against the wall and look underneath. Follow the safety precautions described in section 1-4(2).

To open the front of the cabinet, remove the two screws at the bottom of the front panel. (Figure M-2.) Raise the panel fairly high and the top clips will disengage from the cabinet top. To raise the cabinet top, remove the two screws on the underside of the front corners. Two types of consoles were used in different machines. To open the console, see figure M-2. 7-3 WHAT TYPICALLY GOES WRONG WITH THESE WASHING MACHINES The lid switch plunger is located in the center rear of the lid. With the lid up, NOTHING on these machines works.

I love this film so much, more than the first Avengers. James Spader made the movie for me!

In order to diagnose these machines, you need to keep the lid up far enough to look inside, without tripping the lid switch. You can do this by inserting a putty knife between the lid and the switch, and then propping up the lid with something (I use my electrical pliers to prop up the lid.) The most common ailments in a Maytag washer are leaks, worn belts, and broken timers. SYMPTOM: WATER LEAKS Besides the usual leaky fill solenoid valves, bleach dispensers and such (section 2-4) there are many places that a Maytag washing machine commonly leaks. 1) In the fill line, between the fill solenoid valve and the tub fill nozzle, there is a fill injector which prevents any accidental siphoning of wash water back into your house's fresh water system. (Figure M-3.) This fill injector can get clogged with calcium or other deposits, causing it to back up and leak.